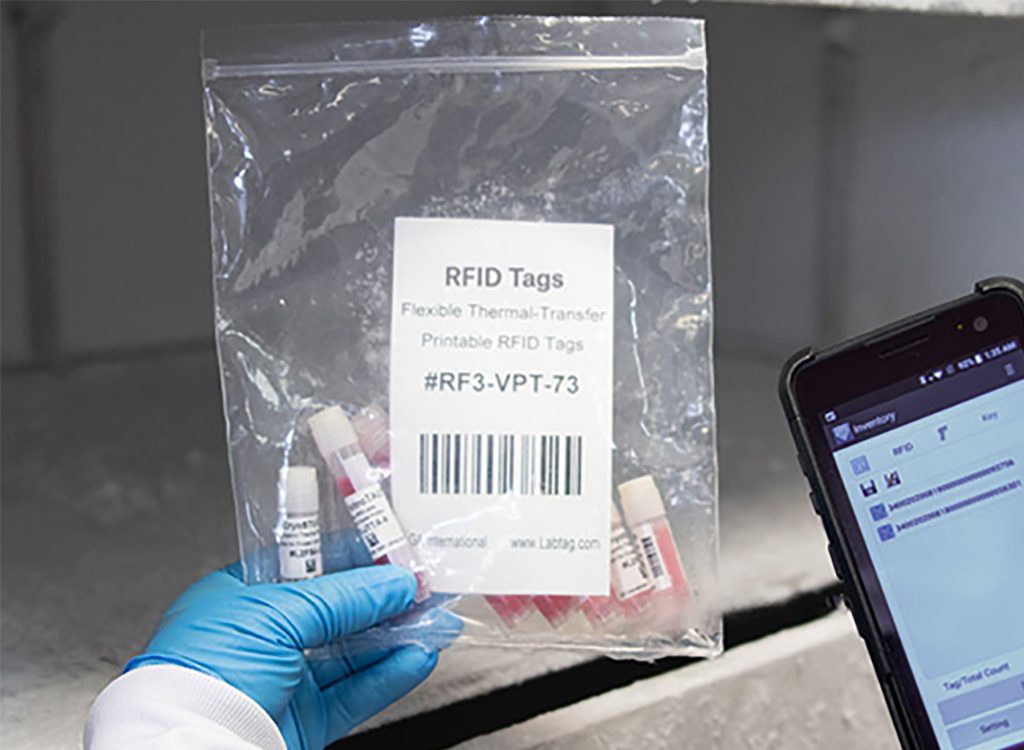

Printable RFID tags represent a significant advancement in information management. By integrating RFID technology with digital printing, these tags not only store and transmit data via radio waves but also allow direct printing of text, barcodes, or QR codes on the surface. This opens up a world of applications across various industries—from manufacturing and logistics to retail.

What Is a Printable RFID Tag?

A printable RFID tag is a type of label that integrates an RFID chip and antenna, enabling wireless communication with RFID readers. Its key features include:

- The internal chip stores and transmits a unique identifier (UID) and additional data such as product serial numbers, manufacturing dates, or warehouse locations.

- The surface can be digitally printed with information, images, barcodes, or QR codes.

This combination significantly enhances personalization and flexibility in information delivery.

The Printing Process for Printable RFID Tags

Printing a printable RFID tag involves a highly technical process that includes:

- Equipment Preparation: Use a specialized printer or a system capable of RFID printing. The printer must be able to activate and encode RFID chips during printing.

- Material Selection: Materials must ensure good conductivity, weather resistance, and compatibility with printing processes to maintain RFID chip integrity and print quality.

- Design Creation: Professional design software is used to generate templates that include required images, text, barcodes, or QR codes.

- Data Integration: Product data is linked with the design template using RFID printing software.

- Printing and Encoding: RFID labels are printed based on predefined settings. During printing, the machine not only applies visuals to the label surface but also activates or encodes the RFID chip. Post-print quality checks ensure all chips are properly functioning.

Versatile Applications of Printable RFID Tags

Printable RFID tags are not merely technological products—they are intelligent solutions applicable across multiple sectors. Their ability to combine RFID functionality with printed data offers exceptional benefits in management, tracking, and asset protection.

Inventory and Retail Management

In retail and warehouse settings, printable RFID tags streamline stocktaking processes, significantly reducing time and labor. Employees can quickly scan inventory with RFID readers. When integrated with POS systems, these tags also enable automated checkout and real-time inventory updates.

Logistics and Supply Chain Management

In logistics, printable RFID tags enable real-time tracking of goods from origin to destination. By tagging parcels and containers, companies can monitor shipment status and location with precision, improving transparency and service quality, while optimizing routes and lowering transport costs.

Asset Tracking and Management

For businesses managing fixed assets, printable RFID tags offer efficient solutions for tracking usage and location. Attaching tags to assets allows real-time monitoring and prevents loss or misuse. Integration with ERP systems further automates asset management and supports data analysis.

Traceability and Anti-Counterfeiting

In industries concerned with product authenticity and food safety, printable RFID tags store data such as batch numbers and distribution history. Consumers can verify product origin by scanning QR codes or barcodes. This enhances consumer protection, combats counterfeiting, and builds trust.

Healthcare and Patient Management

In healthcare, managing pharmaceuticals, medical equipment, and patient records is critical. Printable RFID tags support:

- Efficient Medication Management: Tagging pharmaceutical packaging helps hospitals track inventory and expiration dates, minimizing shortages or expired stock.

- Rapid Patient Identification: Tags attached to wristbands or hospital beds enable quick access to patient data, accelerating service and ensuring safety.

How to Choose the Right Printable RFID Tag

Choosing the appropriate RFID tag is essential to achieving efficiency and cost-effectiveness. Consider the following factors:

- Reading Range: Warehouses may require long-range RFID tags, while small stores or offices may opt for shorter ranges to reduce costs. Select a tag with a reading distance suitable to your environment.

- Storage Capacity: Basic RFID tags store a unique identifier (UID), but high-end tags can hold more data like product serial numbers or batch codes. Choose capacity based on application needs.

- Environmental Durability: For outdoor or harsh conditions, select waterproof, dustproof, or temperature-resistant tags. In food or healthcare, ensure tags meet hygiene and safety standards.

- Printer Compatibility: Tags must be compatible with existing printing equipment and materials to maintain print quality and performance.

- Cost Efficiency: Consider differences in pricing, printing, encoding, and maintenance costs. Choose tags that balance performance, affordability, and durability.

Conclusion

Printable RFID tags are ushering in a new era of information management, offering breakthrough solutions across retail, logistics, asset management, and healthcare. Their fusion of RFID and digital printing enhances workflow efficiency, data accuracy, and operational transparency.

To select the most suitable tag, carefully evaluate reading distance, data capacity, environmental compatibility, printer requirements, and cost. Investing in printable RFID technology is a strategic move that modernizes your operations and strengthens competitive advantage.