RFID technology is rapidly advancing, not only in manufacturing and management but also in everyday life. However, many still have vague questions about what RFID actually is. This article will help clarify the fundamentals of RFID—its definition, features, structure, how it works, and its practical applications.

What is RFID Technology?

RFID (Radio Frequency Identification) is a wireless technology that identifies objects using radio waves. It enables data to be transmitted and received from one point to another via a system of transmitters and receivers, allowing businesses and organizations to track, monitor, or log individual items effectively.

Developed in the 1970s, RFID is now commonly used in daily life—such as car key fobs, toll collection cards, and hotel access cards.

Key Features of RFID Systems

- Wireless communication: RFID uses radio frequency waves for communication, unlike barcodes or QR codes, which rely on optical scanning. This enables non-contact, automatic data exchange.

- Extended readability: RFID can read tags through challenging environments and materials such as concrete, snow, fog, ice, and paint—surpassing barcode or QR code limitations.

- Common frequency ranges: RFID systems often operate at 125kHz or 900MHz.

RFID vs. Barcode vs. QR Code

| Feature | RFID | Barcode | QR Code |

|---|---|---|---|

| Reading Method | Radio frequency | Optical scanner | Optical (laser-based) |

| Line of Sight | Not required | Required | Not required, but limited range |

| Reading Range | Long-range | Short-range | Short-range |

| Read Speed | Fast, multiple tags at once | Slow, one code at a time | Medium speed |

| Durability | Highly durable, reusable | One-time use | One-time use |

| Security | High-level security | Low, easy to counterfeit | Medium security |

| Read/Write Capability | Yes | No | No |

| Cost per Tag | High (up to $50 per tag) | Very low (~$0.01) | Low (~$0.05) |

| Common Use Cases | Anti-theft, asset/machine tracking | Store access, inventory management | Medical, shipping, airline logistics |

| Labor Requirements | Minimal, fully automated | Requires manual scanning | Needs visual display, proper lighting |

| Limitations | May struggle near metal/liquids | Easily damaged, unreadable if dirty | Affected by network/screen quality |

Did you know? NFC (Near-Field Communication) is a newer generation of RFID and is widely used in modern devices and systems.

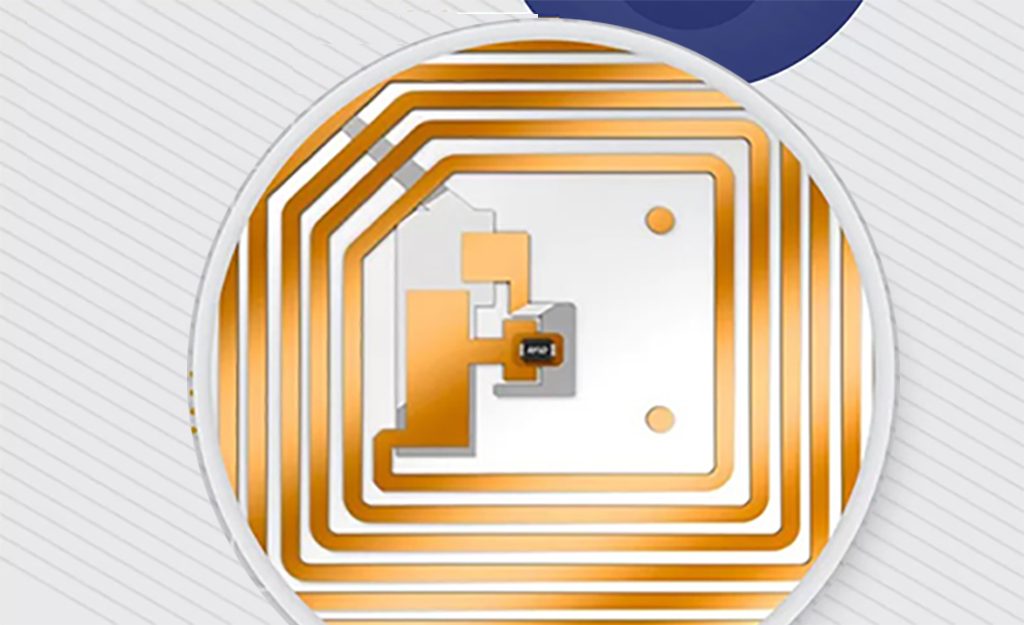

RFID System Components

A complete RFID system includes both hardware and software:

A complete RFID system consists of both hardware and software components:

Hardware

- RFID Tags: Electronically programmed with unique data. Tags can be categorized by frequency (LF, HF, UHF) or type (active, passive, semi-passive).

- RFID Reader: Contains one or more antennas to emit and receive signals. It communicates with enterprise systems by converting tag signals into digital data.

- Antenna: Helps transmit and receive radio waves.

- Server: Hosts the software interface to analyze and process collected data.

- RFID Printer: Used to encode data onto tags if not pre-programmed. Not necessary when using reusable, pre-encoded tags.

Software

- Integration with business systems like ERP, MES, PLM, and SCM allows companies to analyze data in real time, enhancing decision-making processes and overall efficiency.

How RFID Works

RFID operates on a straightforward principle:

- A fixed RFID reader emits radio signals at a specific frequency.

- When an RFID tag enters the signal range, it absorbs the signal and sends back its unique identifier.

- The reader captures this signal and communicates it to the host system, which identifies and logs the tagged object in real time.

RFID Applications in Real Life

RFID in Manufacturing:

Managing inventory and planning across a supply chain is becoming more complex, with various logistical processes such as warehousing, order status, sorting, loading, and customer service. RFID enhances:

- Accuracy in inventory tracking.

- Efficient space utilization.

- Real-time visibility of goods and materials.

By adopting RFID in manufacturing, businesses can form smart factory ecosystems, increase revenue, and reduce operating costs—ultimately boosting competitive advantage.

RFID in Supply Chain & Logistics:

RFID enables real-time tracking of materials and goods, helping businesses:

- Capture critical data on moving items.

- Streamline daily workflows.

- Identify bottlenecks and address them proactively.

- Ensure faster, smarter distribution decisions.

RFID System Deployment Cost

RFID systems can vary significantly in configuration, but generally, they consist of four main components: RFID tags, hardware, software, and related services. To determine ROI before implementing RFID technology, you can consider aspects such as labor savings, increased visibility into production processes and warehouse management, and greater transparency in real-time order tracking. For more information, you can refer to the article “Cost of Implementing an RFID System and How to Calculate ROI” to better understand how to estimate the potential return on investment when deploying an RFID system for your business.

Summary of RFID’s Pros and Cons

Advantages and benefits of RFID

Asset Tracking and Inventory Management:

Tracking assets and materials is a challenge for most organizations—whether it's components on the production line, finished goods in transit, returnable industrial containers, or high-value tools and equipment. RFID systems allow businesses to track these assets quickly and reliably without manually counting each item.

Thanks to RFID, businesses can instantly check the quantity of items in any category, location, or stage in the process—whether they are newly received at the warehouse, issued for production, or have completed the production cycle. This helps manufacturers manage inventory more effectively and enhances their ability to locate misplaced items.

Moreover, RFID-based warehouse management systems enable manufacturers to collect, distribute, verify, and update batch data throughout the lifecycle from inbound to outbound. This reduces labor intensity and minimizes manual errors.

Time and Cost Savings Through Automation:

RFID applications can automatically track the movement of goods and transmit that data into the company’s financial or ERP system. As a result, tasks involving manual form-filling or spreadsheet updates can be fully automated. Fixed readers installed at key points along the production line also help businesses save time and eliminate unnecessary manual intervention.

Improved Data Accuracy and Availability:

Since data is collected and uploaded electronically, RFID helps businesses avoid data duplication, omission, or copying errors—especially in systems that involve a large number of simultaneous operations. Cloud-based systems enable all staff within the organization to access up-to-date information on the location or status of items. In some cases, RFID also facilitates information sharing with customers.

Enhanced Safety and Equipment Longevity:

RFID systems allow companies to track when equipment and vehicles are due for inspection or maintenance and restrict their use if they don't meet specific criteria.

Improved Production Control:

With the ability to identify individual items or components precisely, RFID plays a crucial role in controlling complex manufacturing processes—reducing waste and enhancing efficiency.

Better Quality and Traceability:

RFID systems ensure that items have completed all required processes and passed inspection, enabling businesses to improve quality and significantly reduce returns. Tagging with RFID also ensures traceability by tracking items from their point of origin.

Increased Revenue:

By improving inventory management, organizations using RFID can deliver differentiated services and enhance customer satisfaction—key drivers of higher sales and better profit margins.

Deeper Management Insights:

Because RFID enables real-time data collection across different stages of a product’s lifecycle, it provides more advanced insights for operational and planning purposes. Companies can use this data to further improve their business performance.

Shorter Processes:

RFID can be integrated with other production or supply chain technologies—such as pallet handling systems and automated picking systems—to shorten the time between order placement and delivery.

Quick Return on Investment:

RFID is a highly cost-effective technology. The cost savings and revenue gains it brings can quickly offset the initial investment.

Disadvantages – Challenges of RFID Technology

High Costs of RFID Systems:

Implementing an RFID system can be expensive. RFID requires costly equipment—both hardware and software.

RFID tags can be active, passive, or semi-passive. Although prices have decreased since the 1970s, many companies are still reluctant to adopt RFID due to the cost of the tags.

Issues with Metal and Liquids:

RFID does not perform well around metal and liquids, as radio waves behave unpredictably in metal and can be absorbed by liquids.

To address this, RFID tags used in such environments are typically designed for fast and accurate long-range reading. These tags are thin, compact, waterproof, chemical-resistant, and heat-resistant. Their readability is not affected by metal or water.

Requires In-Depth Technological Understanding:

It can be difficult to understand the various types of RFID tags and their frequencies. Managers need a solid grasp of the technology to properly train staff on managing these systems. Keeping systems updated with the latest tools is also crucial to optimize performance, workflows, and internal communication.

Signal Interference in RFID Systems:

Workers may encounter reader/tag conflicts, such as multiple tags responding simultaneously and causing confusion for the reader.

While it’s undeniable that RFID technology offers many benefits for manufacturing and supply chains, implementing it effectively requires businesses to understand the technology, estimate costs and returns, and anticipate potential challenges.