Radio Frequency Identification (RFID) technology has been around for decades, but only recently have businesses started to fully unlock its potential. RFID is a wireless identification system that transmits data as a unique serial number for each product. It is commonly applied in warehouse management to save time, reduce labor costs, and improve the accuracy of real-time data.

Planning and managing warehouses within the supply chain has become increasingly complex, with logistics activities ranging from storage, order status tracking, sorting, loading/unloading, to customer service. Inefficient use of warehouse space, incorrect identification of goods during receiving and shipping, and misplacement of items can negatively impact productivity, profit, and business reputation.

By applying RFID technology in warehouse management, businesses can enhance supply chain control efficiency—from goods intake to distribution—thereby increasing profit and reducing operational costs.

Benefits of RFID in warehouse management

Implementing RFID technology in warehouse management brings numerous benefits:

- Real-time inventory visibility: RFID-integrated warehouse systems allow businesses to know exactly where and how much inventory exists in real time, significantly reducing overstock and creating smoother operations.

- Accurate tracking and management: RFID helps enhance tracking accuracy and tight inventory control, optimizing labor usage.

- Fewer order entry errors: The integrated system reduces manual intervention, improving staff productivity.

- Lower inventory levels and space requirements: Minimizes excess inventory and warehouse space needs.

- Support for FIFO/LIFO methods: Provides data necessary for managing inventory using FIFO (First-In-First-Out) or LIFO (Last-In-First-Out) methods.

- Instant access to order database: Ensures products are shipped to the correct destination.

- Enhanced data collection: Enables capturing images and documentation related to product conditions, minimizing customer disputes.

Quantifiable benefits of RFID in warehouse management

Effective RFID warehouse management can help manufacturers:

- Reduce inventory by 10%–30%

- Improve warehouse space usage by 20%

- Cut labor costs by 10%–40%

- Increase picking and delivery speed by up to 10%

- Decrease shrinkage/loss by up to 50%

- Boost sales revenue by 2%

- Lower distribution/shipping costs by 2%–13%

- Achieve delivery accuracy above 95%

- Reduce planned return rates by up to 80%

RFID warehouse systems enable mass data collection, distribution, validation, and updates throughout the product lifecycle from intake to daily dispatch. This reduces manual labor and human error. As RFID technology continues to evolve, it is becoming a key factor in enhancing supply chain efficiency and competitiveness.

Warehouses often represent up to 50% of a company’s assets. So, how can businesses organize inventory for better visibility and accessibility? How can warehouse operations be optimized? Please continue to follow and read our upcoming articles.

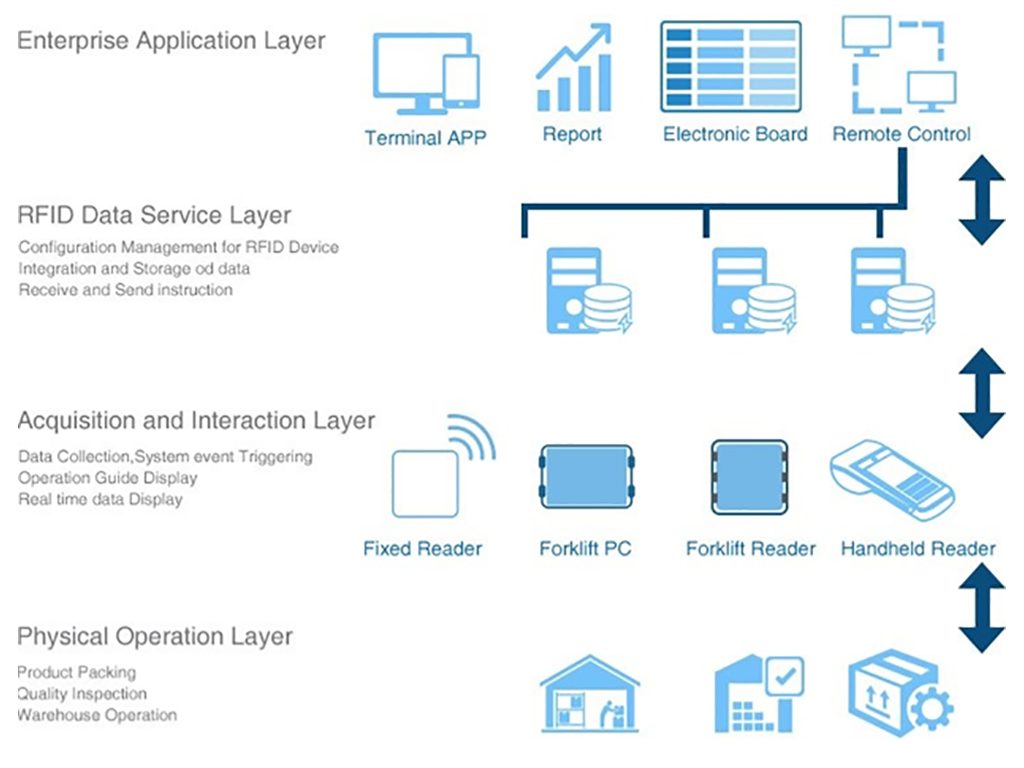

Structure of RFID technology in warehouse management

RFID technology enhances information transparency and automation in manufacturers' warehouse management systems. By connecting to the company's central computer through Electronic Data Interchange (EDI), the system allows the host to collect and display real-time inventory data. Warehouse staff can access the system via wireless networks, handheld electronic devices, and barcode systems to conveniently update and retrieve relevant product information.

Applications of RFID in warehouse management

Implementing RFID technology in inventory management simplifies warehouse control processes:

- Automated Inbound and Outbound Processes: Before goods enter the warehouse, RFID readers are installed. As products pass through the warehouse entrance, RFID readers scan all attached tags, even if not visible, and transmit the data directly to the central system for verification or to create new inbound records. From this point, products are managed via their attached RFID tags.

For outbound processes, RFID inventory checkers verify products against outbound requests. Discrepancies trigger immediate alerts, while matching information allows goods to be dispatched, with the system updating records in real-time. - Locating and Recording Product Positions: Determining the location of specific items within the warehouse is crucial, especially for retailers. RFID technology enables quick identification of product locations, saving time and enhancing customer satisfaction.

- Automated Delivery Verification: All incoming goods are equipped with RFID readers. When selected for dispatch, RFID tags are scanned as items move along conveyors to confirm the accuracy of the shipment. Incorrect items are flagged, and validated products have their data recorded upon dispatch, reducing disputes and compensation claims due to delivery errors.

- Accurate Inventory Audits: RFID's capability to read large quantities accurately allows warehouse staff to conduct efficient inventory audits, saving up to 50% of the time compared to traditional methods.

Comparison: RFID vs. Traditional warehouse management

| Aspect | RFID-Based Management | Traditional Management |

|---|---|---|

| Inventory Audits | Efficient and accurate, saving up to 50% of audit time | Manual, less efficient, higher error rates |

| Inbound/Outbound Processes | Provides precise location information, improving efficiency and reducing delays by 4%-5% | Relies on staff experience, lower efficiency, prone to errors |

| Space Utilization | Accurate storage management, optimizing space usage and reducing inventory costs by 11%-18% | Based on staff experience, higher labor costs |

| Inventory Control | Effectively reduces inventory levels | Difficult to control inventory, requires more labor |

| Locating Products | Accelerates search processes with collected data | Manual searches by staff, time-consuming, higher labor costs |

Adopting RFID technology in warehouse management allows businesses to quickly, efficiently, and automatically count inventory. With RFID readers attached to each specific item, all goods are scanned collectively as they pass through conveyors, ensuring accuracy and eliminating human errors.

RFID technology is revolutionizing warehouse management, offering real-time tracking, improved accuracy, and operational efficiency. Companies like Harrods, LVMH, and Hugo Boss are investing in smart warehousing technologies, including RFID, to enhance their supply chain operations. Additionally, RFID tags are being used in various industries to track inventory goods, providing significant gains in supply chain efficiency.